CHIPS Act and Its Impact on Food Manufacturing in India

When you hear CHIPS Act, a U.S. law designed to boost domestic semiconductor production and reduce reliance on foreign chip supply chains. Also known as the Creating Helpful Incentives to Produce Semiconductors Act, it’s not just about phones and computers—it’s about the machines that make your chips, snacks, and packaged foods. Every automated line in an Indian food factory, from dosa batter mixers to paneer cutters, runs on microchips. When those chips get delayed, production slows down. And that’s exactly what happened during the global shortage.

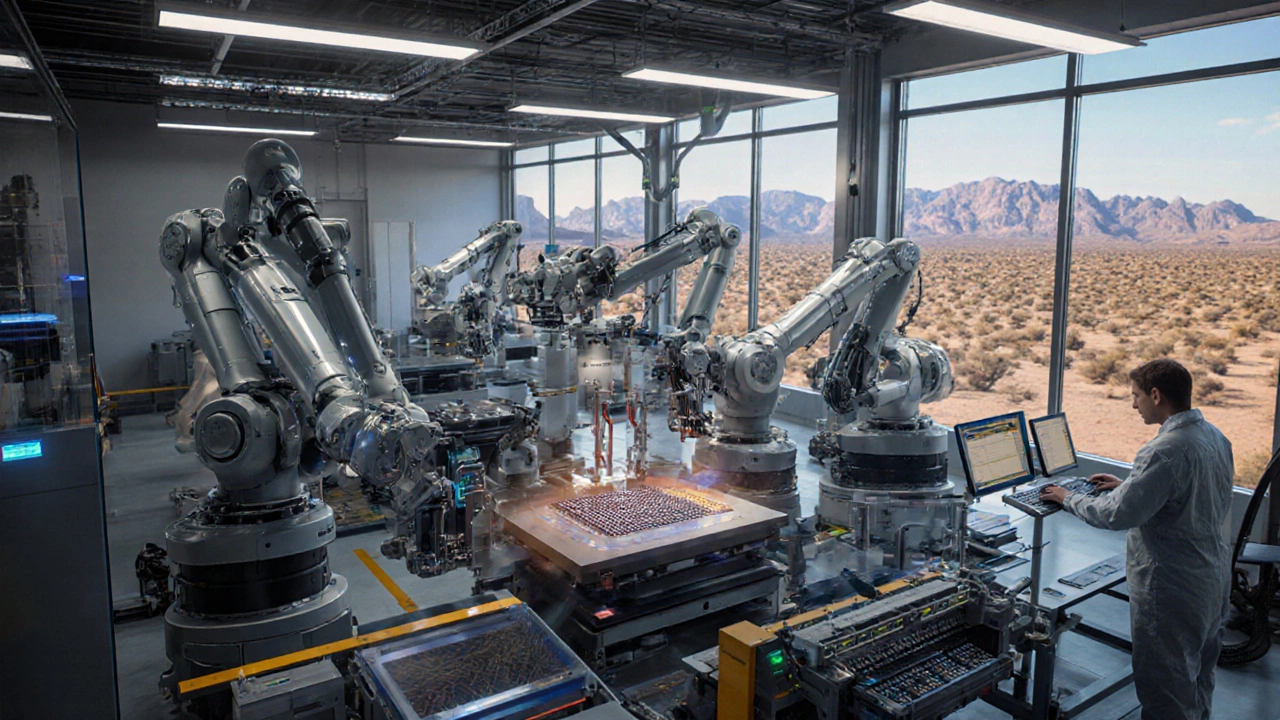

The semiconductor manufacturing, the process of creating tiny electronic circuits used in nearly every modern machine shortage hit Indian food plants hard. Factories that relied on imported control systems for pasteurization, drying, or packaging saw delays of months. Some switched to manual processes. Others scrambled to find alternative suppliers from Vietnam or Thailand. Meanwhile, companies like Amcor and local packaging firms started asking: What if we built more of this stuff here? That’s where the ripple effect begins. The food processing technology, the machinery and automation systems used to turn raw ingredients into safe, shelf-stable products market in India is waking up. Local engineers are now designing simpler, cheaper control units using available chips. Startups are building modular systems that can run on lower-power processors. It’s not about replacing global supply chains—it’s about making them more resilient.

This isn’t just about big factories. Even small makers of homemade paneer or crispy snacks are feeling the shift. If your oven timer, digital scale, or vacuum sealer stops working because it can’t get a new chip, you’re stuck. That’s why more small businesses are now looking at repair, reuse, and local sourcing. The India food industry, the network of manufacturers, suppliers, and distributors producing everything from instant noodles to frozen biryani is learning to adapt—not by waiting for imports, but by fixing what’s broken and building smarter. And that’s where the real innovation is happening.

Below, you’ll find real stories from Indian food makers who’ve had to rethink their machines, their suppliers, and their daily routines. Some switched to manual methods. Others rebuilt their lines with open-source controllers. A few even started making their own circuit boards. These aren’t tech blogs—they’re frontline reports from kitchens and factories that kept running, even when the chips ran out.