Which Chemical Is Highly Used in India? Top Chemicals Driving Industry and Daily Life

Sodium Hydroxide Usage Calculator

How Sodium Hydroxide Powers India's Economy

Sodium hydroxide (NaOH), also known as caustic soda, is India's most widely used chemical. This calculator shows how much NaOH is consumed across key sectors in India based on industry data.

Enter values above to see sodium hydroxide consumption estimates

India uses more than 100 million metric tons of chemicals every year. That’s not just factory smoke and lab bottles - it’s the backbone of everything from the soap you wash with to the fertilizer that grows your food. But if you ask which single chemical is highly used in India, the answer isn’t one you’d guess from a textbook. It’s not gold, not lithium, not even plastic. It’s sodium hydroxide - also called caustic soda.

Sodium Hydroxide: The Invisible Workhorse

Sodium hydroxide (NaOH) shows up everywhere in India’s economy. It’s the key ingredient in soap, detergents, and cleaning agents that households and hotels use daily. But its real power lies in industry. Textile mills in Tamil Nadu and Gujarat rely on it to treat cotton before dyeing. Paper factories in Maharashtra use it to break down wood pulp. And every single aluminum plant in the country needs it to extract pure metal from bauxite ore.

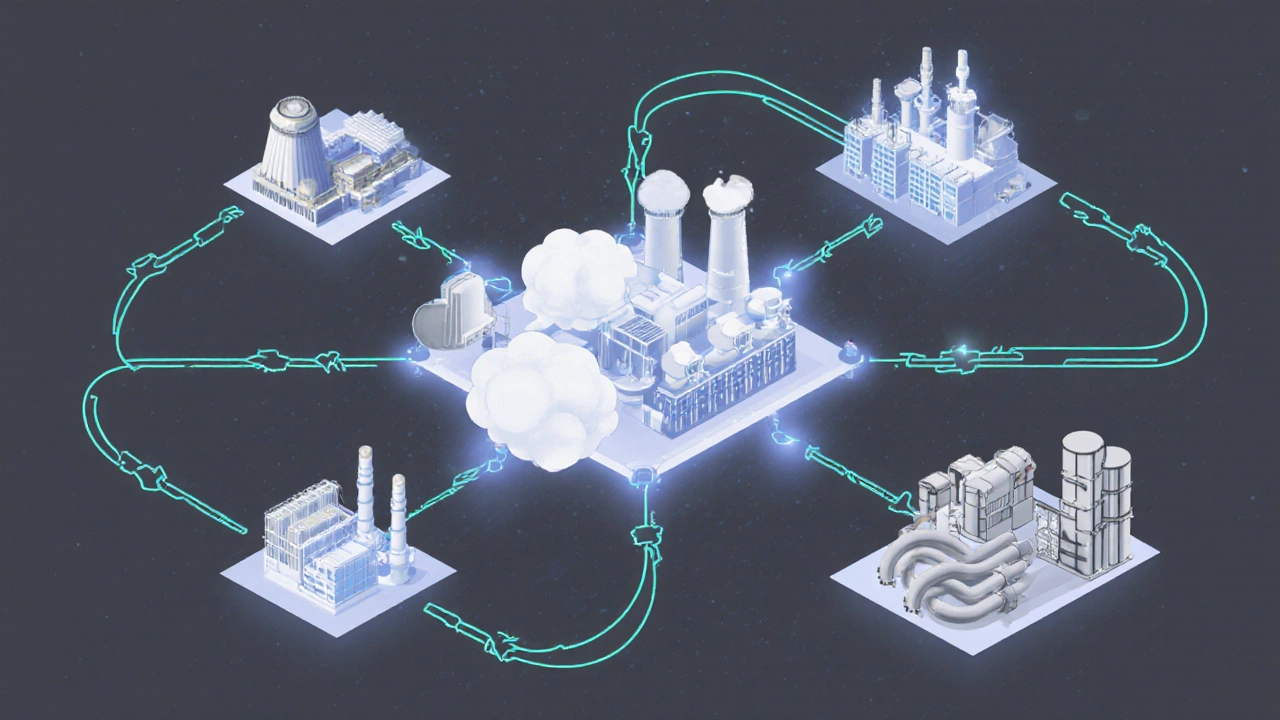

India produces over 2.5 million metric tons of sodium hydroxide annually, and imports another 300,000 tons. Most of it comes from Gujarat and Tamil Nadu, where large chemical plants like Tata Chemicals, Reliance Industries, and Aarti Industries operate. These aren’t small labs - they’re massive facilities running 24/7, feeding demand across the country.

Why sodium hydroxide? Because nothing else does its job as cheaply or efficiently. It’s not flashy, but it’s essential. Without it, India’s detergent market - worth over $4 billion - would collapse. Its role in water treatment alone saves millions from contaminated drinking water.

Chlorine: The Silent Partner

You can’t talk about sodium hydroxide without mentioning chlorine. The two are made together in the same factories through electrolysis of saltwater. Chlorine is what disinfects your tap water in Delhi, Mumbai, and Bangalore. It’s used in PVC pipes, medical equipment, and even the plastic packaging for snacks you buy at the corner store.

India consumes nearly 2 million metric tons of chlorine each year. Over 60% of it goes into making PVC, which is everywhere - from window frames to electrical wire insulation. With India building 12 million new homes every year, demand for PVC - and therefore chlorine - keeps rising. The country produces about 70% of its chlorine needs domestically, but still imports the rest from the Gulf and China.

Chlorine isn’t just for industry. It’s in your bleach, your swimming pool, and the sanitizers you used during the pandemic. It’s the reason India’s public water supply doesn’t turn into a breeding ground for cholera.

Urea: Feeding the Nation

If sodium hydroxide cleans, and chlorine disinfects, then urea feeds. Urea is the most widely used nitrogen fertilizer in India. Farmers apply over 30 million metric tons of it every year to grow rice, wheat, and sugarcane. That’s more than any other chemical used in agriculture.

India is the second-largest consumer of urea in the world, after China. The government subsidizes it heavily - over $10 billion a year - to keep food prices low. There are 27 major urea plants across the country, mostly run by public sector companies like FCI and Indian Farmers Fertiliser Cooperative (IFFCO).

But there’s a problem. India still imports nearly 30% of its urea because domestic production can’t keep up with demand. This makes the country vulnerable to global price spikes. When Russia’s exports dropped in 2022, urea prices jumped 40% overnight. Farmers in Punjab and Uttar Pradesh felt it immediately.

Other Heavyweight Chemicals in India

While sodium hydroxide, chlorine, and urea lead the pack, other chemicals play massive roles:

- Sulfuric acid - used in fertilizer production (especially phosphates), metal processing, and battery manufacturing. India produces over 12 million tons a year.

- Ammonia - the base for urea and other nitrogen fertilizers. Mostly made from natural gas, and imported when gas prices rise.

- Phthalic anhydride - key for making plasticizers used in PVC and paints. Most of it comes from Gujarat-based chemical firms.

- Hydrochloric acid - used in steel cleaning, food processing, and water treatment. Often made on-site by industries to cut costs.

These aren’t niche chemicals. They’re the hidden gears turning India’s economy. A single steel plant in Jamshedpur uses over 100 tons of hydrochloric acid every week to clean raw iron. A single paint factory in Hyderabad uses 15 tons of phthalic anhydride daily.

Why India Depends on These Chemicals

India’s population of 1.4 billion means demand is massive - and non-negotiable. You can’t feed 1.4 billion people without fertilizer. You can’t clean 600 million homes without detergent. You can’t build roads, homes, and power lines without PVC and plastics. And you can’t make any of those plastics without chlorine and sodium hydroxide.

The chemical industry in India is worth over $200 billion. It employs more than 3 million people directly and supports another 10 million in related sectors like agriculture, textiles, and construction. That’s more than the entire IT sector.

What’s changing? More companies are shifting to green chemistry - using renewable feedstocks and reducing waste. But the core chemicals remain the same. Sodium hydroxide, chlorine, and urea aren’t going anywhere. They’re too deeply woven into India’s daily life.

Who Makes These Chemicals in India?

India’s chemical manufacturing is dominated by a few big players, but hundreds of small factories fill the gaps:

- Tata Chemicals - largest producer of soda ash and sodium bicarbonate, also makes chlorine and caustic soda.

- Reliance Industries - produces chlorine, PVC, and phthalic anhydride at its Jamnagar complex.

- Aarti Industries - key supplier of specialty chemicals for dyes, pharmaceuticals, and agrochemicals.

- Deepak Nitrite - major producer of sodium nitrite and nitro compounds used in dyes and explosives.

- IFFCO - largest urea producer in India, operates 11 plants across the country.

- CCIL (Chloro Chemicals India Limited) - one of the top chlorine and sodium hydroxide producers in Gujarat.

Outside these giants, thousands of small and medium enterprises (SMEs) make specialty chemicals for local markets - from laundry detergents in Rajasthan to textile dyes in West Bengal. Many of them rely on bulk chemicals from the big producers, then mix and package them locally.

What’s Next for Chemicals in India?

India’s chemical industry is shifting. The government’s Production Linked Incentive (PLI) scheme now offers up to 15% cashback on sales for companies making high-value chemicals like specialty polymers and active pharmaceutical ingredients. This is pushing companies to move beyond bulk commodities.

But the big three - sodium hydroxide, chlorine, and urea - will remain king. Why? Because they’re not luxury items. They’re necessities. The next 10 years will see more recycling of chlorine-based plastics, better fertilizer efficiency, and cleaner production methods. But the demand? It’s only going up.

As India urbanizes, builds more homes, and feeds more people, the need for these chemicals won’t slow down. They’re not glamorous. But without them, India’s economy would grind to a halt.

What is the most used chemical in India?

The most used chemical in India is sodium hydroxide (caustic soda). It’s essential for soap, detergent, paper, textiles, and water treatment. India produces over 2.5 million metric tons annually, and it’s used across nearly every major industry.

Is urea a chemical used in India?

Yes, urea is the most widely used fertilizer in India. Farmers apply over 30 million metric tons every year to grow food crops like wheat and rice. The government heavily subsidizes it to keep food affordable, making it one of the most important chemicals in Indian agriculture.

Which Indian companies produce chlorine and sodium hydroxide?

Major producers include Tata Chemicals, Reliance Industries, Aarti Industries, and CCIL (Chloro Chemicals India Limited). Most of these companies operate in Gujarat and Tamil Nadu, where saltwater feedstock and infrastructure support large-scale production.

Why does India import chemicals like urea and ammonia?

India imports urea and ammonia because domestic production can’t meet demand, especially when natural gas prices rise. Urea production requires natural gas as feedstock, and India doesn’t produce enough gas to run all its plants at full capacity. Imports help fill the gap, especially during peak farming seasons.

Are there environmental concerns with chemical use in India?

Yes. Overuse of urea leads to soil degradation and water pollution. Chlorine byproducts can contaminate water if not handled properly. But the industry is moving toward greener methods - recycling waste, using renewable energy, and reducing emissions. The government is pushing for cleaner production through its PLI scheme and stricter environmental norms.

What Should You Do If You’re in the Chemical Business?

If you’re a manufacturer, supplier, or buyer of chemicals in India, here’s what matters:

- Focus on sodium hydroxide, chlorine, and urea - they’re the backbone. Even niche businesses rely on them.

- Build relationships with big producers in Gujarat and Tamil Nadu. They control bulk supply and pricing.

- Watch government policy. Subsidies, import duties, and PLI schemes change fast - and they affect your costs.

- Don’t ignore small markets. Local detergent makers, textile units, and fertilizer retailers need steady, reliable suppliers.

- Start thinking about sustainability. Buyers are asking for eco-certified chemicals. Even basic sodium hydroxide can be produced with lower carbon footprints now.

The chemical industry in India isn’t about flashy innovation. It’s about reliability, scale, and necessity. The next time you wash your hands, clean your floor, or eat rice, remember - sodium hydroxide made it possible.