What Small Business Is the Most Successful? Top Manufacturing Ideas That Actually Work

Manufacturing Profit Margin Calculator

Business Inputs

Niche Insights

Based on the article, successful niche manufacturing businesses typically maintain 50-70% profit margins.

Example: Food packaging services with 60%+ margins (Article mentions 50-70% for this niche).

Common pitfalls from the article:

- Underpricing to "get started"

- Building products nobody asked for

- Ignoring regulatory requirements

Profit Analysis

When people ask, "What small business is the most successful?" they’re usually looking for a magic formula - something simple, low-cost, and guaranteed to make money. The truth? There’s no single answer. But in manufacturing, success doesn’t come from chasing trends. It comes from solving real problems with reliable, repeatable processes. And in 2025, the most successful small manufacturing businesses aren’t the biggest. They’re the ones that focus on niche demand, local supply chains, and high-margin custom work.

Why Small Manufacturing Still Wins in 2025

Big factories get all the attention, but the real growth is happening in workshops, garages, and small industrial units. In the UK, over 12,000 small manufacturing firms added jobs between 2022 and 2024, according to the Federation of Small Businesses. Why? Because customers are tired of cheap, mass-produced junk. They want products that are made locally, built to last, and tailored to their needs.

Take a small metal fabrication shop in Birmingham. Five years ago, they were struggling to compete with Chinese imports. Now, they specialize in custom brackets for solar panel installers. No one else in the West Midlands does it with the same precision, and they charge £85 per bracket - up from £18 in 2020. Their profit margin? 68%. That’s not luck. That’s strategy.

The Top 5 Most Successful Small Manufacturing Business Ideas

Not all manufacturing ideas are equal. Some require heavy machinery, big loans, and years of training. Others can start with a CNC router, a 3D printer, and a website. Here are the five that consistently deliver strong returns with low overhead:

- Custom metal components for niche industries - Think agricultural equipment repair shops, eco-friendly builders, or local bike frame makers. These clients don’t want off-the-shelf parts. They need exact fits, specific alloys, and quick turnaround. A small shop with two CNC machines can easily hit £200k in annual revenue with 15-20 regular clients.

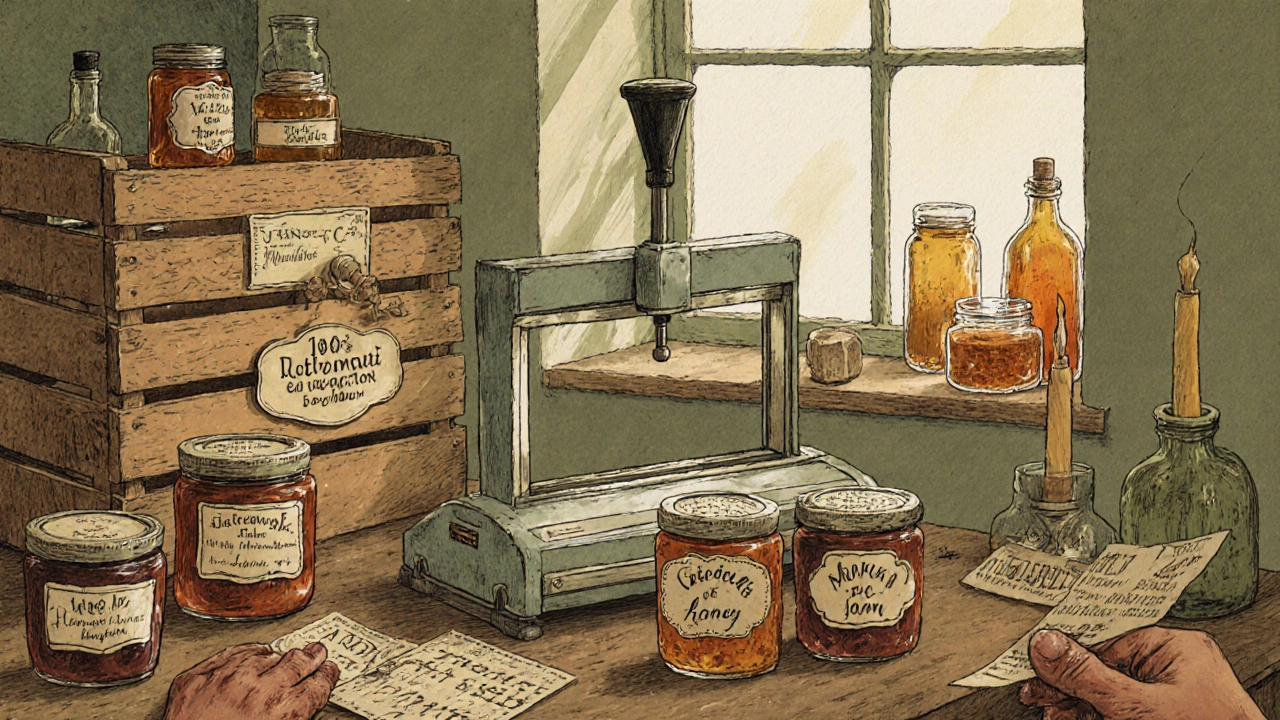

- Small-batch food packaging and labeling - Artisanal jams, organic honey, craft spirits - these products need labels that stand out. A small print-and-pack operation using digital label printers and heat-sealing machines can serve 50+ local producers. Margins: 50-70%. Setup cost: under £15k.

- 3D-printed replacement parts for vintage appliances - Old washing machines, typewriters, even 1980s stereo systems. People don’t want to throw them out. They want to fix them. A single 3D printer, some scanning software, and a Shopify store can turn broken gadgets into a steady income. One shop in Leeds makes £12k/month selling replacement knobs, gears, and housings.

- Custom plastic injection molding for local startups - You don’t need a huge factory. Small injection molding machines (like the Haitian 120T) can run on a 10x10m floor. Local product designers need prototypes and small runs (50-500 units). Charge £250 per mold setup and £1.20 per unit. Profit per order? Often £400-£1,200.

- Recycled material products (upcycled timber, reclaimed metal art) - Waste isn’t trash. It’s inventory. A small workshop taking discarded pallets, old steel beams, or broken furniture can turn them into wall art, coffee tables, or garden planters. One couple in Cornwall started with £3k in scrap and now sell £800 pieces at craft fairs and Etsy. Their material cost? Under £15 per item.

What Makes These Businesses Work?

These aren’t just ideas. They’re proven models. Here’s what they all have in common:

- They solve a specific pain point - Not "people need stuff," but "people need this exact part that no one else makes locally."

- They avoid commoditization - If Amazon sells it for £5, you’re not competing. You’re selling something you can’t find online.

- They use lean equipment - You don’t need a 10-machine factory. One good machine, well-used, beats ten idle ones.

- They sell direct - No middlemen. No distributor cuts. Shopify, Instagram, or even local trade shows keep margins high.

- They build relationships, not just sales - One client becomes five through word of mouth. That’s how these businesses scale without advertising budgets.

Common Mistakes That Kill Small Manufacturing Businesses

Too many people start a manufacturing business thinking it’s about machines. It’s not. It’s about customers.

Here are the top three reasons small manufacturing businesses fail:

- Building something nobody asked for - One guy in Sheffield spent £20k on a laser cutter to make custom keychains. He sold three in six months. Meanwhile, a nearby shop making replacement latches for vintage car doors? Sold 300 in the same time.

- Underpricing to "get started" - Charging £5 for a custom bracket that costs £3 in materials and 45 minutes of labor? You’re not building a business. You’re working for free.

- Ignoring regulation - If you’re making food packaging, electrical enclosures, or children’s toys, you need CE marking, food-grade materials, or EN71 safety standards. Skipping this isn’t saving money - it’s inviting a lawsuit.

How to Start With Under £5k

You don’t need a loan. You don’t need investors. Here’s how one person in Derby started a profitable manufacturing side hustle in 90 days with £4,200:

- Spent £1,800 on a used desktop 3D printer (Creality Ender 3 V2).

- Spent £600 on PLA and ABS filament, plus a small filament dryer.

- Spent £500 on a used laptop for design work (Fusion 360 free for hobbyists).

- Spent £800 on a Shopify store and basic product photography.

- Spent £500 on targeted Facebook ads to local antique repair shops.

Within three months, he was selling replacement clock gears, vintage radio knobs, and model train couplers. His average sale? £32. Monthly profit? £2,100. He didn’t quit his job. He just added a business that runs itself after hours.

Where to Find Your First Customers

Forget cold calling. The best customers are already online - they’re just not looking for you yet.

- Facebook Groups - Search "vintage appliance repair UK," "small farm equipment fix," "craft brewery equipment." Post photos of your parts. Answer questions. Be helpful.

- Etsy and eBay - List your custom parts as "handmade," "custom made to order," or "for vintage [X]." Use keywords like "replacement," "custom fit," "made in UK."

- Local trade fairs - Go to farmers’ markets, craft shows, or industrial expos. Bring samples. Talk to the people fixing things. They’ll become your referral network.

- Instagram Reels - Show the process: "How I turned a broken washing machine part into a new one in 3 hours." People love seeing the transformation.

Final Thought: Success Isn’t About Size - It’s About Specificity

The most successful small manufacturing business isn’t the one with the most machines. It’s the one that knows exactly who it serves, what they need, and why they can’t get it anywhere else. It’s not about being the biggest. It’s about being the only one who does it right.

Start small. Solve one real problem. Build trust. Then, do it again. That’s how real manufacturing success is built - one custom part at a time.

What small manufacturing business has the highest profit margin?

Small-batch food packaging and labeling often have the highest margins - between 50% and 70%. These businesses use low-cost digital printers and heat-sealing machines to serve local artisans like jam makers, honey producers, and craft distillers. The product itself is made by the client; your job is just packaging and labeling. Material costs are low, and you charge per unit with minimum order quantities. One operator in Wales makes over £4,000/month with just two machines and six regular clients.

Can I start a manufacturing business without a factory?

Absolutely. Many successful small manufacturers operate from garages, workshops, or rented industrial units. A 3D printer, CNC router, or small injection molding machine can fit in a 10x10m space. The key is focusing on high-margin, low-volume custom work. For example, a maker in Manchester runs a profitable business from his garage making custom plastic fittings for model railways. He doesn’t need a factory - he needs customers who need exactly what he makes.

Do I need special certifications to start manufacturing?

It depends on what you’re making. If you’re producing food contact items, children’s toys, or electrical enclosures, you’ll need CE marking, EN71 safety standards, or food-grade material certifications. For general metal or plastic parts used in machinery or decor, no formal certification is required - but you still need to follow basic safety and quality practices. Always check the UKCA marking requirements for your product category. Skipping this can lead to fines or product recalls.

How long does it take to make a profit in small manufacturing?

With the right niche and lean setup, you can turn a profit in 60-90 days. For example, a 3D printing service for replacement parts can start taking orders the same week you launch your Shopify store. The key is targeting a problem people are actively searching for solutions to. Avoid building products in a vacuum. Talk to repair shops, hobbyists, or small businesses first. Your first 10 sales will come from people who already know they need what you’re making.

Is manufacturing a good side hustle in 2025?

Yes - if you treat it like a business, not a hobby. Manufacturing side hustles thrive when they solve real, recurring problems. Making custom brackets for solar installers, printing labels for local honey makers, or 3D-printing replacement parts for old appliances are all side hustles that can earn £1,500-£3,000/month part-time. The trick is consistency. Work on it after hours, track your costs, and focus on repeat customers. It’s not glamorous, but it’s reliable.

If you’re thinking about starting a small manufacturing business, don’t wait for the perfect moment. Start with one machine, one customer, and one problem you can solve better than anyone else. The rest will follow.