What Are the 7S of Manufacturing? A Clear Guide to Lean Workplace Organization

7S Implementation Savings Calculator

Calculate your potential time, cost, and safety improvements by implementing the 7S methodology in your manufacturing facility.

Estimated Implementation Benefits

The 7S of manufacturing aren’t a government scheme. They’re a practical, hands-on system used in factories, workshops, and production lines around the world-including right here in India-to cut waste, boost safety, and make work easier. If you’ve ever walked into a messy factory where tools disappear, machines break down often, or workers seem frustrated, you’ve seen what happens when the 7S aren’t followed. This isn’t theory. It’s what keeps factories running smoothly day after day.

What Exactly Are the 7S?

The 7S model started in Japan as an extension of the older 5S system. It adds two more elements to help organizations build a culture of discipline and continuous improvement. Each S stands for a Japanese word, but in practice, they’re translated into simple English actions that anyone can understand and apply.

Here are the 7S:

- Sort - Remove everything you don’t need.

- Set in Order - Put what’s left where it belongs.

- Shine - Clean everything, every day.

- Standardize - Make rules so everyone does it the same way.

- Sustain - Keep it up, even when no one’s watching.

- Safety - Make sure nothing hurts anyone.

- Self-Discipline - Everyone takes personal responsibility.

It’s not a checklist you fill out once. It’s a habit. And when it’s done right, it changes how people think about their work.

Sort: Get Rid of the Clutter

Think about your garage. You keep that old drill because ‘you might need it someday.’ In a factory, that same mindset turns into a warehouse of broken tools, expired parts, and unused machines taking up space.

Sorting means asking: ‘Do I use this? Has it been used in the last 30 days?’ If the answer is no, it gets tagged, moved to a holding area, and then either thrown out, recycled, or stored off-site.

A factory in Pune cut its floor space by 30% in six weeks just by sorting. They found 17 machines that hadn’t been used in over two years. One was a CNC machine that was still plugged in-just gathering dust. That space became a new inspection station. Productivity went up. Accidents dropped.

Set in Order: Everything Has a Home

Once you’ve removed the junk, what’s left needs a place. Not just ‘somewhere.’ A specific, labeled, easy-to-find spot.

Shadow boards for tools. Floor markings for carts. Color-coded bins for parts. Labels in both English and the local language. This isn’t about being neat-it’s about saving time.

One small auto parts maker in Gujarat tracked how long it took workers to find a specific wrench. Before 7S: 4 minutes. After: 12 seconds. That’s 180 hours saved per worker per year. Multiply that by 50 workers? That’s 9,000 hours. That’s more than four full work years. All from putting tools back where they belong.

Shine: Clean to See Problems

Shining doesn’t mean mopping the floor. It means cleaning so you can spot issues. A leaky pipe. A loose bolt. Oil pooling under a machine. A crack in a bearing.

When workers clean their own area every morning, they start noticing things they never saw before. A vibration that wasn’t there last week. A strange noise when the motor starts. These are early warnings.

In a pharmaceutical plant in Hyderabad, a routine cleaning revealed a tiny crack in a pipe that was slowly leaking solvent. They fixed it before it caused a shutdown or contamination. That one clean spot saved them over ₹12 lakh in lost production and fines.

Standardize: Make It Repeatable

One person might clean their station perfectly. Another might skip it. That’s not a problem with the people-it’s a problem with the system.

Standardizing means writing down how things should be done. Photos. Checklists. Videos. Step-by-step instructions posted right where the work happens.

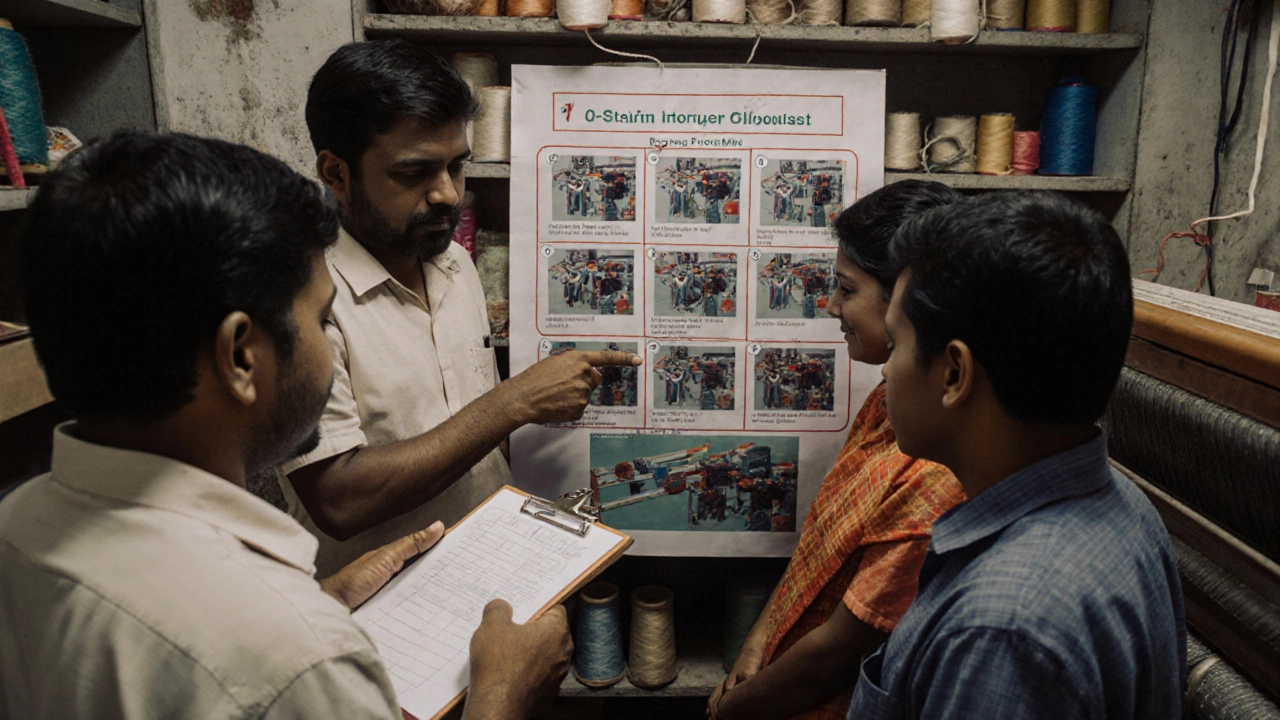

A textile mill in Tiruppur created a 10-step visual guide for setting up looms. Before: new hires took 3 weeks to get up to speed. After: they were productive in 3 days. Mistakes dropped by 60%. And the quality of fabric improved because no one was guessing how to do it.

Sustain: Make It Stick

This is where most companies fail. They do a big 7S push. Clean everything. Mark everything. Then, three months later? Back to chaos.

Sustaining means making 7S part of daily life. Daily 10-minute clean-ups. Weekly audits. Monthly team reviews. Recognition for the cleanest station. A simple scoreboard with photos of the top three areas each month.

One electronics assembly unit in Bengaluru started a ‘7S Champion’ award. Workers nominated each other. Winners got a small gift and their photo on the wall. Within six months, 92% of teams were maintaining their standards without reminders.

Safety: The Foundation of Everything

You can’t have efficiency if someone gets hurt. That’s why safety isn’t just the sixth S-it’s the reason all the others exist.

Sorting removes tripping hazards. Setting things in order means cords aren’t stretched across walkways. Shining reveals spills before someone slips. Standardizing includes safety procedures. Sustaining means safety is never ignored.

In a chemical plant in Vadodara, they added a simple rule: ‘No open containers on the floor.’ Before: 12 minor spills a month. After: 1. No injuries. No cleanup costs. No downtime.

Self-Discipline: The Hidden Key

Self-discipline is the quietest S. It’s not a policy. It’s a mindset.

It’s when a worker picks up a dropped screw even though it’s not their area. It’s when someone says, ‘Hey, that tool’s not in its spot,’ without being asked. It’s when people stop thinking ‘that’s not my job’ and start thinking ‘this is our place.’

This doesn’t come from posters or training sessions. It comes from leadership. Managers who clean their own workstations. Who show up early. Who follow the rules they set.

At a small gear factory in Chennai, the owner started arriving 15 minutes early every day to do his 7S routine. Within a year, every employee did the same. No one was told to. They just started doing it.

Why the 7S Work Better Than Any App or Software

There are apps that track inventory. Software that schedules maintenance. But none of them fix human behavior. The 7S work because they change how people think.

They don’t require big budgets. You don’t need AI or IoT sensors. You need time. Consistency. And a willingness to look at your own space and say, ‘This can be better.’

Companies that use the 7S see results like:

- 30-50% reduction in setup time

- 40-60% fewer machine breakdowns

- 20-30% less material waste

- 50% drop in workplace injuries

- Higher morale and lower turnover

These aren’t guesses. These are numbers from real factories across Tamil Nadu, Maharashtra, Uttar Pradesh, and Karnataka. The same results show up in small workshops and large plants alike.

Where the 7S Don’t Work

They don’t work when:

- Leaders don’t participate. If the boss doesn’t clean their desk, why should the worker clean theirs?

- It’s treated like a one-time project. 7S isn’t a campaign. It’s a way of life.

- People are punished for mistakes instead of being helped to improve.

- There’s no follow-up. No audits. No recognition.

The biggest mistake? Thinking it’s about cleanliness. It’s not. It’s about control. Control over your environment. Control over your time. Control over your quality.

How to Start With the 7S

You don’t need to overhaul your whole factory. Start small.

- Pick one station. One machine. One team.

- Get everyone together. Show them what 7S looks like.

- Do a 2-hour sorting session. Remove everything unnecessary.

- Label everything. Take before-and-after photos.

- Make a daily 5-minute cleaning routine.

- Review progress every Friday.

If it works there? Expand. Slowly. Consistently. That’s how real change happens.

Final Thought: It’s Not About Rules. It’s About Respect.

The 7S aren’t about control. They’re about respect-for your tools, your space, your coworkers, and yourself.

When you walk into a place where everything has its place, where the floor is clean, and the tools are ready, you feel it. You feel like you’re part of something that matters. That’s the real power of the 7S. Not in the numbers. In the feeling.

Are the 7S of manufacturing a government scheme in India?

No, the 7S of manufacturing are not a government scheme. They are a lean manufacturing methodology developed in Japan and adopted globally by factories to improve efficiency, safety, and discipline. While the Indian government promotes manufacturing through schemes like Make in India or PLI, the 7S system is a voluntary, workplace-driven practice used by private and public sector factories alike.

What’s the difference between 5S and 7S?

The original 5S system includes Sort, Set in Order, Shine, Standardize, and Sustain. The 7S adds two more: Safety and Self-Discipline. Safety makes sure the workplace doesn’t cause harm, and Self-Discipline ensures that people follow the rules even without supervision. The 7S version is more complete because it addresses human behavior and well-being, not just physical organization.

Do I need special training to implement the 7S?

No, you don’t need formal training. The 7S are simple enough that anyone can understand them. What you need is leadership-someone willing to start, show the way, and keep the team focused. Many factories in India begin with a single team, use photos and checklists, and build from there. Training can help, but it’s not required to get results.

How long does it take to see results from the 7S?

You’ll notice small improvements within days-like less time spent searching for tools. Major results, like fewer machine breakdowns or lower waste, usually show up in 4 to 8 weeks. Real cultural change-where people naturally follow the system-takes 6 to 12 months. The key is consistency, not speed.

Can small workshops use the 7S too?

Absolutely. In fact, small workshops benefit the most. With limited space and fewer staff, every minute and every tool counts. A small metal fabrication shop in Coimbatore cut its setup time by 45% and doubled its daily output just by applying the 7S to its two machines and one workbench. Size doesn’t matter-commitment does.